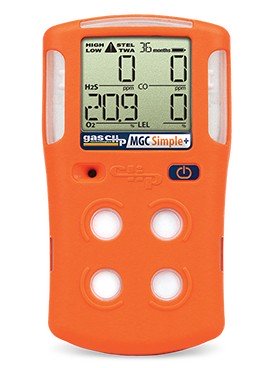

MGC-Simple Multi-Gas Monitor: The 2-Year Solution for Continuous Gas Detection

In high-risk work environments where toxic gases pose serious threats to worker safety, reliable gas detection isn't optional—it's essential. Yet traditional multi-gas monitors come with a frustrating reality: constant charging, frequent calibration, and the very real possibility that someone forgets to maintain the equipment when it's needed most. The Gas Clip Technologies MGC-Simple changes that equation entirely.

What is the MGC-Simple?

The MGC-Simple (model MGC-S) is a personal 4-gas detector that monitors for the most common hazardous gases encountered in industrial environments:

- H₂S (Hydrogen Sulfide) - The "sewer gas" that's deadly even in low concentrations

- CO (Carbon Monoxide) - The silent killer with no odor or color

- O₂ (Oxygen) - Monitors for both oxygen deficiency and enrichment

- LEL (Lower Explosive Limit) - Detects combustible gases before they reach dangerous levels

What sets the MGC-Simple apart from every other multi-gas detector on the market? Two revolutionary features: no charging ever and no calibration necessary. Once activated, this detector runs continuously for two full years, then it's replaced. That's it.

The Technology Behind the 2-Year Runtime

How does Gas Clip Technologies achieve what seems impossible—a multi-gas detector that runs for 24 months straight without a single charge?

Advanced Infrared Technology

The secret lies in their proprietary low-power photometric infrared (IR) technology for combustible gas detection. Traditional multi-gas monitors use pellistor sensors for LEL detection, which are power-hungry and drain batteries quickly. The MGC-Simple's IR sensor:

- Consumes dramatically less power

- Is immune to sensor poisoning from H₂S and silicone compounds

- Works in oxygen-enriched and oxygen-deficient environments

- Doesn't require oxygen to detect gas (unlike catalytic sensors)

This single innovation extends battery life from days or weeks to literally years.

Sealed, Non-Replaceable Battery

The MGC-Simple uses a high-capacity sealed battery that's designed to last exactly as long as the sensor elements. There's no battery compartment to open, no charging port to plug in, and no opportunity for the detector to die mid-shift because someone forgot to charge it overnight.

Why "No Calibration Necessary" Matters

Every safety manager knows the calibration headache. Traditional gas monitors require:

- Monthly bump tests

- Quarterly calibrations

- Expensive calibration gas

- Dedicated staff time

- Careful record-keeping for compliance

The MGC-Simple eliminates all of this. While the detector can be calibrated if required by specific regulations or company policy, it's designed and factory-calibrated to maintain accuracy for its entire 2-year lifespan without field calibration.

What does this mean in practical terms?

- No calibration gas purchases

- No time lost to calibration procedures

- No compliance paperwork for calibration schedules

- No uncertainty about whether the detector is properly maintained

Simply activate it, assign it to a worker, and it's good for two years.

Real-World Applications

Oil & Gas Operations

In oilfield operations where H₂S is a constant threat, the MGC-Simple provides peace of mind:

- Drilling operations

- Well servicing

- Pipeline work

- Tank cleaning and maintenance

- Confined space entry

Workers in remote locations don't need to worry about access to charging stations or calibration equipment. The detector just works.

Wastewater and Utilities

Municipal wastewater facilities face some of the most dangerous gas hazards:

- Sewer line maintenance

- Lift station work

- Treatment plant operations

- Manhole and vault entry

The MGC-Simple handles the constant exposure to H₂S and provides reliable detection in the humid, corrosive environments common in wastewater work.

Construction and Industrial

General contractors, industrial facilities, and maintenance crews benefit from the simplicity:

- Confined space work

- Welding and hot work

- Facility maintenance

- Underground utility work

- Industrial plant shutdowns and turnarounds

Emergency Response

First responders and hazmat teams need equipment they can grab and trust:

- Fire department operations

- Emergency rescue

- Hazmat incidents

- Industrial emergencies

No time to check if the monitor is charged or calibrated—the MGC-Simple is always ready.

Design Features That Make a Difference

Simple One-Button Operation

Complexity is the enemy of safety. The MGC-Simple features truly simple operation:

- Press and hold the single button to activate

- Wait less than 65 seconds for sensor warm-up

- Clip it on and go to work

That's it. No menu navigation, no complicated setup, no user error.

Large, Easy-to-Read Display

In an emergency, you need to see alarm conditions instantly. The MGC-Simple provides:

- High-contrast LCD screen

- Clear gas reading numbers

- Distinctive alarm icons

- Visible in various lighting conditions

- Readable with safety glasses or face shields

Robust Alarm System

When gas is detected, you'll know immediately through three simultaneous alarm modes:

- Visual: Bright flashing alarm indicators

- Audible: 95+ decibel alarm (louder than most job site noise)

- Vibrating: Physical vibration you can feel even in noisy environments

This triple-redundant alarm system ensures workers are alerted regardless of environmental conditions.

Durable Construction

Built for the real world, not the lab:

- IP65 rated (dust-tight and water-resistant)

- Impact-resistant housing

- Operating temperature: -20°C to 50°C (-4°F to 122°F)

- Intrinsically safe for use in hazardous locations

- Sturdy alligator clip that grabs tight and stays put

Continuous Data Logging

The MGC-Simple logs gas readings every second for the entire 2-year lifespan. This provides:

- Complete exposure records

- Incident documentation

- Compliance evidence

- Safety program analysis data

Data is downloaded using the optional GCT IR Link communication module.

Understanding the Sensors

H₂S (Hydrogen Sulfide) Detection

Hydrogen sulfide is one of the most dangerous gases in industrial settings. Even at low concentrations, it can cause respiratory paralysis and death. The MGC-Simple's H₂S sensor provides early warning before dangerous exposure occurs.

Why H₂S is dangerous:

- Paralyzes the sense of smell at higher concentrations (you can't smell it to know it's there)

- More toxic than carbon monoxide

- Heavier than air, accumulates in low areas

- Common in oil/gas, wastewater, and agricultural operations

CO (Carbon Monoxide) Detection

Carbon monoxide is a silent killer—odorless, colorless, and toxic. The MGC-Simple monitors CO levels continuously, critical in any environment where combustion occurs.

CO hazards include:

- Internal combustion engines

- Gas-powered equipment in enclosed spaces

- Incomplete combustion of any fuel

- Welding and cutting operations

O₂ (Oxygen) Monitoring

Too little oxygen causes unconsciousness and death. Too much oxygen creates fire and explosion hazards. The MGC-Simple monitors both conditions.

Oxygen risks:

- Displacement by inert gases (nitrogen, argon, CO₂)

- Consumption by decomposition or oxidation

- Enrichment from leaking oxygen equipment

- Natural depletion in confined spaces

LEL (Lower Explosive Limit) Detection

Combustible gases create explosion hazards long before reaching flammable concentrations. The MGC-Simple's IR sensor detects these gases and warns workers before conditions become immediately dangerous.

LEL monitoring is critical for:

- Natural gas leaks

- Gasoline and solvent vapors

- Methane in sewers and landfills

- Any environment with flammable gases

The Total Cost of Ownership Advantage

Let's break down the real costs of gas detection:

Traditional rechargeable multi-gas monitor (2-year period):

- Initial purchase: $800-1,200

- Calibration gas: $300-500

- Bump test gas: $200-300

- Replacement sensors: $400-600

- Labor for testing/calibration: $500-1,000

- Total: $2,200-3,600

MGC-Simple (2-year period):

- Initial purchase: Typically $600-800

- Calibration: $0 (not necessary)

- Bump testing: $0 (or minimal if required by policy)

- Replacement parts: $0 (sealed unit)

- Labor: $0 (no maintenance needed)

- Total: $600-800

The MGC-Simple delivers professional-grade gas detection at a fraction of the total cost.

Accessories and Support Equipment

While the MGC-Simple works perfectly as a standalone detector, several accessories enhance its functionality:

MGC Simple Dock

The portable testing dock allows you to:

- Perform bump tests if required

- Calibrate detectors when needed

- Download data logs

- Store and charge the IR Link module

MGC Simple Wall Mount Dock

The wall-mounted version provides:

- Permanent testing station

- Gas compartment with regulator

- Multiple detector capacity

- Built-in data logging via USB

External Pump (GCT-XP)

Converts the MGC-Simple into a sample-draw detector:

- Remote sampling up to 75 feet

- Useful for pre-entry testing

- Probe entry into spaces before worker entry

- Sample flow greater than 1 foot per second

Confined Space Kit

Complete kit for confined space work includes:

- Sampling probe

- Sampling hose

- Hand aspirator pump

- Calibration accessories

- IR Link communication module

- Hard-sided carrying case

GCT IR Link

Download data from your MGC-Simple:

- Connects via USB to Windows PC

- Downloads complete exposure records

- Generates compliance reports

- Software included

Compliance and Certifications

The MGC-Simple meets or exceeds requirements for:

- OSHA confined space regulations (29 CFR 1910.146)

- NIOSH recommendations

- ANSI/ISA 12.13.01 performance requirements

- CSA C22.2 No. 152 certification

- IECEx and ATEX certifications (international)

The detector is intrinsically safe for use in Class I, Division 1 hazardous locations.

Setup and Operation: It Really is Simple

Initial Activation:

- Remove detector from packaging

- Press and hold the power button for approximately 3 seconds

- Release button when display activates

- Wait for sensor warm-up (indicated by "chasing zeros" on display)

- After 65 seconds, all sensors are active and monitoring

Daily Use: The detector runs continuously once activated. No daily startup required. Simply:

- Check that the display shows all gas readings

- Verify battery indicator shows adequate charge

- Ensure all alarm ports are clear of debris

- Clip to shirt, vest, or hard hat and begin work

At End of Shift: Leave it running. The 2-year runtime assumes 24/7 operation.

After 2 Years: Replace the entire unit with a new MGC-Simple. Dispose of the old unit according to local electronic waste regulations.

Common Questions Answered

Q: What happens if I need to calibrate for regulatory compliance? A: The MGC-Simple can be calibrated using the MGC Simple Dock or Wall Mount Dock with standard calibration gas (25 ppm H₂S, 100 ppm CO, 18% O₂, 50% LEL methane).

Q: Can I turn it off to extend battery life? A: You could, but it's not necessary. The 2-year runtime assumes continuous operation. Turning it off doesn't significantly extend the lifespan since the sensors have a 2-year chemical life regardless of power state.

Q: What if it gets wet? A: The IP65 rating means it's protected against water jets from any direction. It will continue operating if splashed or rained on. However, it's not submersible.

Q: How do I know the battery is getting low? A: The display shows a battery status icon. When battery capacity drops below 10%, you'll get visual and audible low-battery warnings. At this point, the detector should be replaced.

Q: Can replacement sensors be installed? A: No. The MGC-Simple is a sealed unit designed for 2-year operation then replacement. This eliminates the possibility of incorrect sensor installation and ensures the entire unit is refreshed on schedule.

Q: Is it compatible with older GCT docking stations? A: The MGC-Simple requires the MGC Simple Dock or MGC Simple Wall Mount Dock. It's not compatible with the original MGC docks designed for rechargeable models.

Q: What gases does the LEL sensor detect? A: The IR sensor responds to most combustible gases including methane, propane, butane, and gasoline vapors. It's factory-calibrated for methane but cross-references other gases. Note: It will NOT detect hydrogen (H₂) or acetylene (C₂H₂).

Q: What if there's a sensor fault? A: The MGC-Simple performs continuous self-diagnostics. If a sensor fails, you'll get a fault alarm. The detector should be replaced immediately.

When the MGC-Simple Makes Perfect Sense

The MGC-Simple is ideal when:

- You have workers in remote locations where charging and calibration are impractical

- You manage a large fleet of monitors and want to eliminate maintenance logistics

- You need simple operation for workers with varying technical abilities

- You want to reduce total cost of ownership for gas detection

- You require 24/7 protection without worrying about battery life

- You need documented compliance without complex calibration records

When You Might Choose a Rechargeable Model

Consider the rechargeable Multi Gas Clip (MGC) if:

- You have easy access to charging and calibration facilities

- You prefer the lower initial cost with higher ongoing maintenance

- You need features like adjustable alarm setpoints

- You have dedicated safety staff managing equipment

The Bottom Line: Simple Really is Better

In safety equipment, complexity creates risk. Every step in a procedure is an opportunity for error. Every piece of equipment that requires maintenance is a potential point of failure.

The MGC-Simple eliminates these risks. Turn it on, clip it on, trust it for two years. No training required beyond basic alarm response. No maintenance schedule to manage. No wondering if someone forgot to charge it last night.

For companies serious about gas detection but tired of the maintenance burden of traditional monitors, the MGC-Simple represents a fundamental shift in how portable gas detection can work. It's not just simpler—it's smarter.

Available at CSP Forestry & Supply

CSP Forestry & Supply stocks the complete line of Gas Clip Technologies gas detectors, including the MGC-Simple and all accessories. Since 1986, we've been supplying safety equipment to the oilfield, pipeline, construction, and industrial sectors.

Why buy from CSP Forestry?

- Expert guidance: Our team understands gas detection and can help you select the right equipment

- Competitive pricing: Direct relationships with manufacturers mean better prices for you

- Complete solutions: We stock monitors, docks, accessories, and calibration gas

- Fast shipping: Get your safety equipment when you need it

- Industry experience: We've been serving your industry for nearly four decades

Don't let gas detection complexity put your workers at risk. Contact CSP Forestry & Supply today to learn more about the MGC-Simple and how it can simplify your safety program.

Call us at 1-800-592-6940 or email sales@csp.supply

Your workers deserve simple, reliable protection. The MGC-Simple delivers.

About Gas Clip Technologies

Based in Cedar Hill, Texas, Gas Clip Technologies has revolutionized portable gas detection with their focus on simplicity and reliability. Their innovative approach to low-power sensor technology has made truly maintenance-free gas detection a reality. All GCT detectors are assembled in the USA and backed by a 2-year warranty.

About CSP Forestry & Supply

Since 1986, CSP Forestry & Supply has been a trusted source for professional-grade safety equipment, forestry supplies, oilfield products, and industrial tools. We serve customers across the United States with quality products, competitive pricing, and the expertise that comes from decades of industry experience. Visit us at www.cspforestry.com or call 1-800-592-6940.

Keywords: MGC-Simple, gas monitor, 4-gas detector, H2S detector, CO detector, oxygen monitor, LEL detector, multi-gas monitor, Gas Clip Technologies, portable gas detector, oilfield safety, confined space monitor, no calibration gas detector