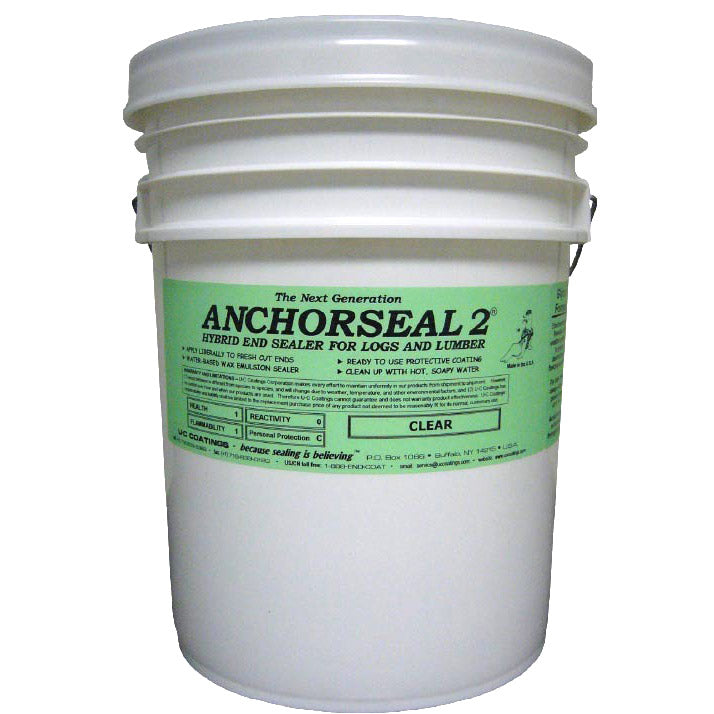

Anchorseal 2 Clear End Sealer: Protect Your Logs and Lumber the Right Way

There's a moment every sawmill operator, logger, and woodworker knows all too well. You've just felled a beautiful timber or run a fresh board through the mill — and within hours, the ends start to crack. Those splits aren't just cosmetic. They eat into your yield, reduce the value of your lumber, and can ruin wood that took years to grow. The good news? There's a proven solution that's been protecting logs and lumber for over four decades. It's called Anchorseal 2 Clear End Sealer, and it remains the gold standard in the industry for a reason.

What Exactly is Anchorseal 2?

Anchorseal 2 is a hybrid wax emulsion end sealer manufactured by U-C Coatings out of Buffalo, New York. It's designed to do one thing exceptionally well: prevent up to 90% of end checking (drying splits) in freshly sawn logs, lumber, ipe decking, turning blanks, and other green wood components.

The "Clear" version dries completely transparent, meaning it protects without altering the look of your wood — a major plus for high-value lumber and decking projects where appearance matters.

What Makes It Different from the Original Anchorseal?

U-C Coatings introduced the original Anchorseal back in 1980, and it quickly became the industry standard. Anchorseal 2 is the next evolution of that formula. Anchorseal 2 is a hybrid sealer that contains renewable, natural ingredients so there is less petroleum-based material used in production. The result is a greener, more economical product that drips less, sticks better, has improved stability and, best yet, better than the original Anchorseal.

In short — everything you loved about the original, improved.

Why End Checking Happens (And Why It Matters)

Before diving into how Anchorseal 2 works, it helps to understand the problem it solves.

Wood dries unevenly, and moisture loss through the end grain happens much faster than through the face grain. This rapid drying can result in end checking, warping, and structural weaknesses that shorten the lifespan of wood.

Think of it this way: the ends of a log or piece of lumber are essentially open channels where moisture rushes out. The sides of the wood dry slowly and evenly. That mismatch in drying speed creates stress — and that stress shows up as cracks, splits, and checks right at the ends.

For loggers and sawmill operators, end checking is a direct hit to the bottom line. Checked lumber loses grade, loses value, and sometimes becomes unusable entirely. For woodworkers and furniture builders, it can ruin a project before it even starts.

The Cost of Doing Nothing

End checking isn't just an aesthetic inconvenience. The economic impact adds up fast:

- Reduced lumber grades — Checked lumber often drops one or more grades, significantly lowering its market value

- Wasted material — Severe checking forces you to cut off affected ends, reducing usable length

- Rejected product — Customers and inspectors reject visibly checked lumber, especially in decking and finish applications

- Slower inventory turnover — Damaged lumber sits longer, tying up yard space and capital

A single gallon of Anchorseal 2 costs a fraction of what one rejected load of lumber is worth. The math is simple.

How Anchorseal 2 Actually Works

Anchorseal 2 is a hybrid of new technology polymers and petroleum wax that protects the ends of logs and lumber. It is known in the forest products industry as the best quality and most stable wax emulsion end sealer available.

When you apply Anchorseal 2 to the freshly cut end of a log or piece of lumber, the hybrid wax formula penetrates into the open end grain and creates a flexible, protective barrier. This barrier doesn't stop moisture from leaving the wood entirely — that would actually cause its own problems — but it dramatically slows the rate of moisture loss through the ends. The result is that the ends and the sides of the wood dry at a much more even rate, which is exactly what prevents checking and splitting.

The clear formula dries to an almost invisible finish, so the sealer does its work without leaving any visible residue or discoloration on the wood.

What Can You Use Anchorseal 2 On?

This is one of the great things about Anchorseal 2 — its versatility. It can be applied to all species of hardwood or softwood. Here's a rundown of the most common applications:

Sawmill and Logging Operations

This is where Anchorseal 2 earns its keep for most forestry professionals. Fresh-sawn logs and lumber need to be sealed as soon as possible after cutting. Whether you're running a large commercial sawmill or a small backyard band mill, applying Anchorseal 2 right after sawing protects your investment before end checking has a chance to start.

Exotic and Tropical Hardwood Decking

When carefully applied to the freshly cut ends of tropical hardwoods, such as ipe, Brazilian walnut, mahogany and tigerwood, Anchorseal 2 prevents up to 90% of end checking, protecting your investment and extending the life of the deck. Exotic decking boards are expensive. Protecting those cut ends is a no-brainer.

Wood Turning Blanks

Woodturners know the frustration of watching a beautiful blank crack overnight. Anchorseal and Anchorseal 2 can prevent up to 90% of end checks and drying splits on turning blanks, cookies, and live-edge slabs — giving you time to let the wood dry properly before you get to work on it.

Live-Edge Slabs and Furniture

Live-edge slabs are trendy, valuable, and incredibly susceptible to end checking. Sealing the exposed ends with Anchorseal 2 helps these slabs dry slowly and evenly, preserving the natural beauty that makes them so desirable in the first place.

Log Homes and Post-and-Beam Construction

Logs destined for log home construction need to be protected during the drying and seasoning process. Anchorseal 2 keeps those logs stable and crack-free while they season — whether that's months or even a year or more.

The Green Factor

In today's market, sustainability isn't just a buzzword — it's a buying decision. Anchorseal 2 checks the box here too. It is made of plant-based polymers and wax, is non-hazardous, water-based, and contains no solvents. Cleanup is simple soap and water. No harsh chemicals, no respirator required, no hazardous waste disposal to worry about.

For operations that care about their environmental footprint — and increasingly, for customers who ask about it — Anchorseal 2 is a product you can feel good about using.

An Added Bonus: Blue Stain Prevention

Here's something that doesn't get talked about enough. Anchorseal 2 can help reduce blue stain in logs. Blue stain is caused by fungi that thrive in the moisture-rich environment of freshly cut wood. By sealing the ends quickly and slowing moisture loss, Anchorseal 2 creates conditions that are less hospitable to the fungi responsible for blue stain and sapstain. It's not a guarantee, but it's a meaningful added layer of protection.

Color Coding: More Than Just Clear

While the Clear version is the most popular, Anchorseal 2 is available in clear or more than 35 colors. This opens up a practical advantage that sawmill operators love: you can easily brand or color code your lumber by species or customer.

Imagine being able to look across your lumber yard and instantly identify which logs are oak, which are walnut, and which are destined for a specific customer — all with a single swipe of color-coded end sealer. It's a small detail that adds real efficiency to a busy operation.

How to Apply Anchorseal 2

Getting the most out of Anchorseal 2 comes down to timing and technique. Here's what you need to know:

Timing is Everything

For freshly cut logs and lumber, apply Anchorseal as soon as possible. Wood can start to check within hours of being cut, so sealing early is key to reducing moisture-related damage. The sooner you seal, the better your results. Waiting even a day or two can mean checking has already begun, and once it starts, no amount of sealer will fully reverse it.

Application Methods

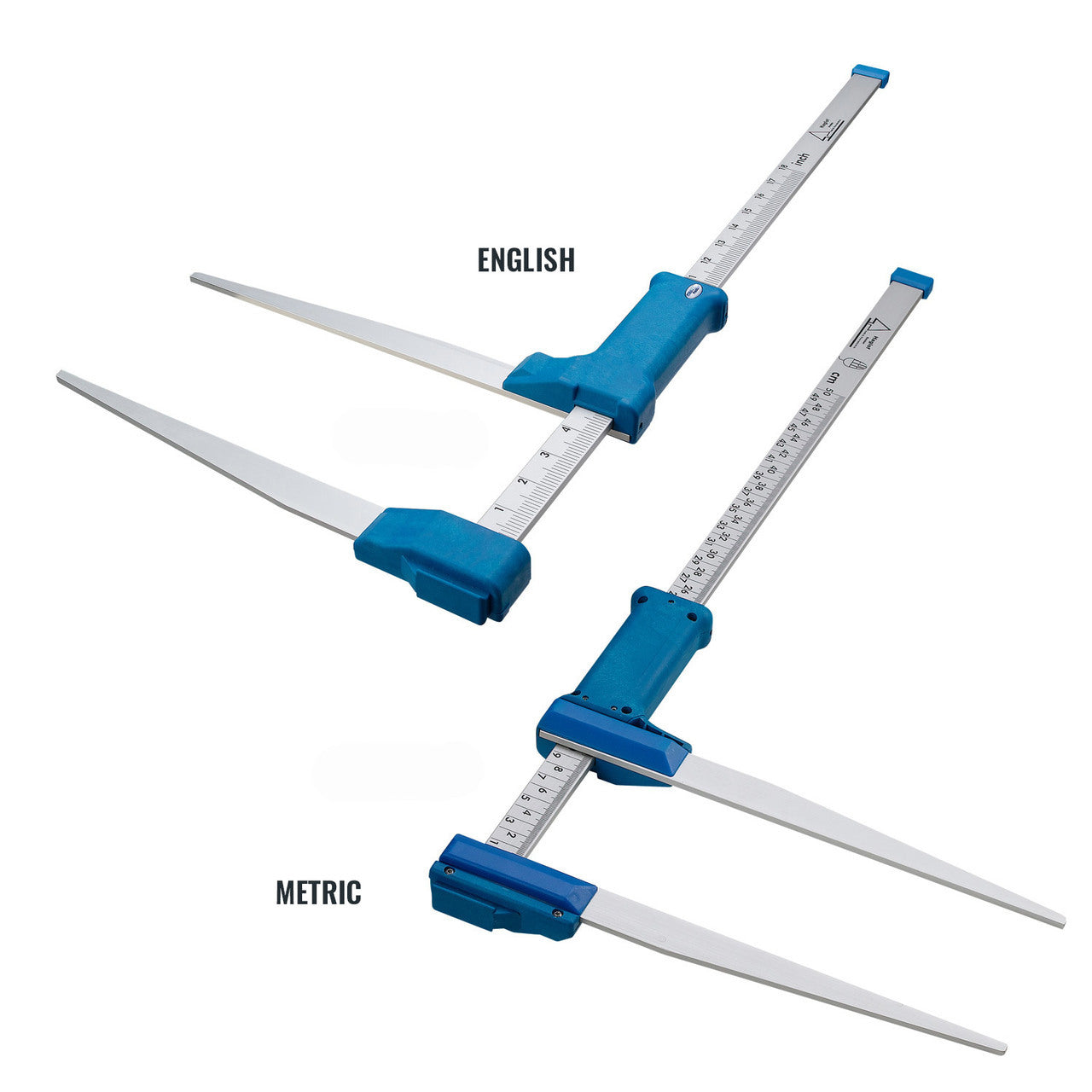

Depending on the size of the project, different application methods may work best: Brush – Best for small projects like woodturning blanks and slabs. Roller – Ideal for sealing multiple boards quickly. Sprayer – The most efficient choice for large-scale applications, such as logs or stacks of lumber.

For sprayer users, if using spray equipment other than those sold by U-C Coatings, use a 0.21"/0.55 mm tip or larger.

Coverage and Thickness

Approximate coverage is 100 square feet per gallon, though this varies depending on species and application method. The goal is a thick, even coat that fully saturates the end grain. Don't be shy with it — a thin coat won't do the job.

Logs larger than 24"/60 cm in diameter will require a heavier coating, or two coats must be applied within a 15 minute period. Bigger logs have more end grain to seal, and more moisture trying to escape.

Drying and Curing

Once applied, the sealer will dry to the touch within a few hours, but it is recommended to leave the wood undisturbed for at least 24 hours to allow for full absorption. During this time, avoid direct exposure to rain or extreme sunlight, as these conditions can interfere with the drying process.

Deck Board Tips

If you're sealing the cut ends of decking boards, apply Anchorseal 2 carefully with a thin brush or sponge applicator. To avoid potential staining, do not allow Anchorseal 2 to get on the face of the boards. A little care here goes a long way.

Storage

Store unused Anchorseal 2 above 50°F/10°C to prevent freezing. Winterized formulas will protect against freeze damage. If you're in a region with cold winters, make sure you're using the winterized version during the colder months.

Anchorseal 2 vs. DIY Alternatives

You might have heard of people using latex paint, driveway sealer, or other home-remedies to seal log ends. While some of these might slow checking a little, they fall short in several important ways:

- Latex paint cracks and flakes as the wood moves, leaving the end grain exposed again

- Driveway sealer is rigid and doesn't flex with the wood, leading to failure as the wood dries and shrinks

- Generic sealers aren't formulated to penetrate end grain effectively, leaving gaps where moisture escapes

Anchorseal 2 is specifically engineered for this one job. It's flexible, it penetrates deeply, and it's been proven over decades of real-world use. Anchorseal was introduced as a wax-based end sealer designed to protect the ends of logs and lumber from rapid moisture loss, which can cause end-checking and degrade the quality of the wood. The product's effectiveness and ease of application quickly made it a preferred choice among professionals. There's a reason it's still the go-to after all these years.

Who Needs Anchorseal 2?

If any of the following describe you, Anchorseal 2 belongs in your supply kit:

Sawmill operators who need to protect fresh-sawn lumber during drying and storage. Every board you protect is a board you don't have to throw away or sell at a lower grade.

Loggers who fell and buck timber in the field. Sealing log ends before they go to the mill or the yard keeps the wood in prime condition.

Woodturners and hobbyist woodworkers who want to dry their own blanks and slabs without the heartbreak of watching them crack.

Contractors and decking installers working with exotic hardwoods like ipe, teak, or cumaru who need to protect expensive material from end checking after cutting to length.

Log home builders who need seasoning logs to stay stable and crack-free during the building process.

Available at CSP Forestry & Supply

We carry Anchorseal 2 Clear End Sealer here at CSP Forestry & Supply, and it's one of those products our customers keep coming back for. Once you see the difference it makes on your logs and lumber, you won't go back to anything else.

We stock it in the sizes that work for both small woodworking shops and large-scale sawmill and logging operations. Whether you need a single gallon or a 5-gallon pail, we've got you covered.

Why buy from CSP Forestry?

- We've been supplying the forestry and lumber industry since 1986

- Competitive pricing on all UC Coatings products

- Fast shipping to get it to you when you need it

- Expert team that can answer questions about application and best practices

- Complete selection of logging and sawmill supplies

Don't let end checking eat into your profits or ruin your projects. Anchorseal 2 is one of the simplest, most cost-effective investments you can make in protecting your wood.

Order today at www.cspforestry.com or call us at 1-800-592-6940.

About U-C Coatings

U-C Coatings, based in Buffalo, New York, has been an industry leader in wood protection products since 1980. Their Anchorseal line of end sealers has been the trusted choice of sawmill operators, loggers, woodworkers, and contractors for over four decades.

About CSP Forestry & Supply

Since 1986, CSP Forestry & Supply has been a go-to source for professional-grade forestry, logging, sawmill, and outdoor supplies across the United States. We stock trusted brands, offer competitive pricing, and back everything up with the kind of expertise that comes from decades in the industry. Visit us at www.cspforestry.com or call 1-800-592-6940.

Keywords: Anchorseal 2, end sealer, end grain sealer, log end sealer, lumber end sealer, end checking prevention, drying splits, sawmill supplies, green wood sealer, wood turning blanks, ipe end sealer, UC Coatings, forestry supplies